After spending some more time with this 3D printer, and UNIZ, I still have some mixed feelings which make recommending a SLASH difficult to do. There are definitely some pros to owning a UNIZ SLASH, but it is certainly not without its cons. Plagued by design flaws, poor design decisions, iffy customer support, underdeveloped “features,” and more… somehow the SLASH printers do still seem to work, when they work.

A LITTLE HISTORY ON THE ORIGINAL SLASH

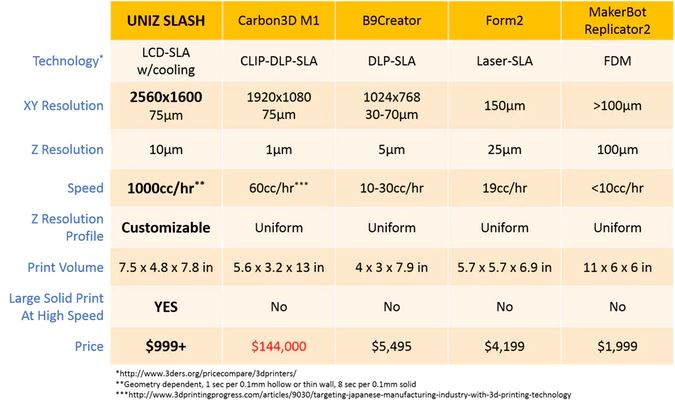

The little known company now known as UNIZ (which appears to be based in San Diego, California, but is run by the same folks who run their assembly warehouse in China) launched their initial Kickstarter campaign for “SLASH: The Next Level of Affordable Professional 3D Printer” on March 29th, 2016. “In just 4 hours, SLASH … reached the initial goal of $50,000,” and on April 28th, 2016 UNIZ “Successfully raised $571,926 with 552 backers” to bring their 3D printer to life. During the campaign UNIZ promised that the SLASH would be fast, high-resolution, and that it would be delivered in December of 2016.

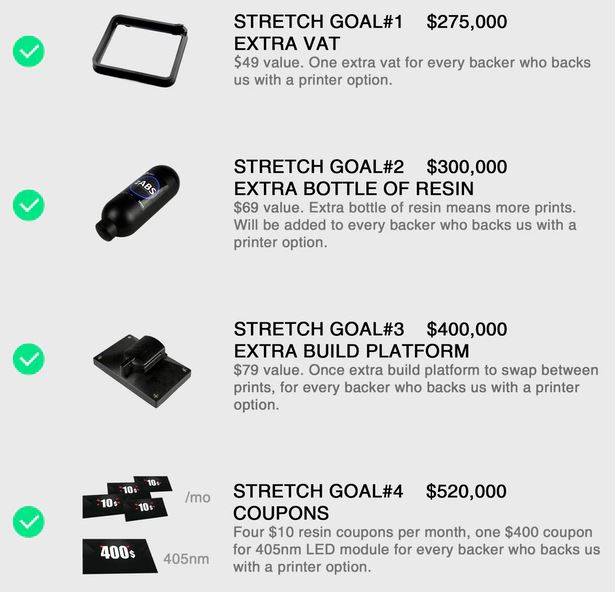

Because of their huge success, UNIZ added stretch goals which were all reached, so they also ended up promising to ship each backer an extra bottle of resin, an extra resin vat, and an extra build platform. They even offered a huge discount on their 405nm LED module (which I ordered, then cancelled, and I do not believe anybody actually received this due to UNIZ changing their plans). A few months later, UNIZ even added what seemed like an awesome bonus feature to the SLASH, a built-in webcam for remote print monitoring.

INITIAL UNIZ CUSTOMER SUPPORT EXPERIENCE

Shortly after the Kickstarter campaign ended, I decided that I wanted to have two SLASH printers when they were ready to ship (I originally pledged enough to get one SLASH printer during the campaign) . So I paid UNIZ a somewhat discounted price directly through their web site for a second machine (but I still paid more than the Kickstarter price for the second machine).

After the official delivery month of December 2016 came and went, I got impatient. By late 2016 I decided that I no longer wanted that second printer. Dealing with UNIZ to get this unfulfilled order cancelled and refunded was worse than having teeth pulled, and by the time they gave me a refund, they refunded and cancelled my Kickstarter pledge instead of the second printer order which I paid more for. It was an even bigger struggle to get UNIZ to understand the mistake they had made (I also lost some access to the Kickstarter campaign). I only wanted the original SLASH printer I paid for through the Kickstarter campaign. Instead of just giving me a refund of the difference of the price of the two orders, UNIZ asked me to send them the full amount that I had originally paid through Kickstarter, but this time through PayPal. This did not make any sense to me, and I eventually decided to ask UNIZ to refund all of my orders. It was clear to me after these interactions that UNIZ has zero customer service experience, and English was unfortunately not their first language which made it that much more difficult (and of course, I do not speak any Chinese)…

DELIVERY, UNPACKING, AND

FIRST IMPRESSIONS I

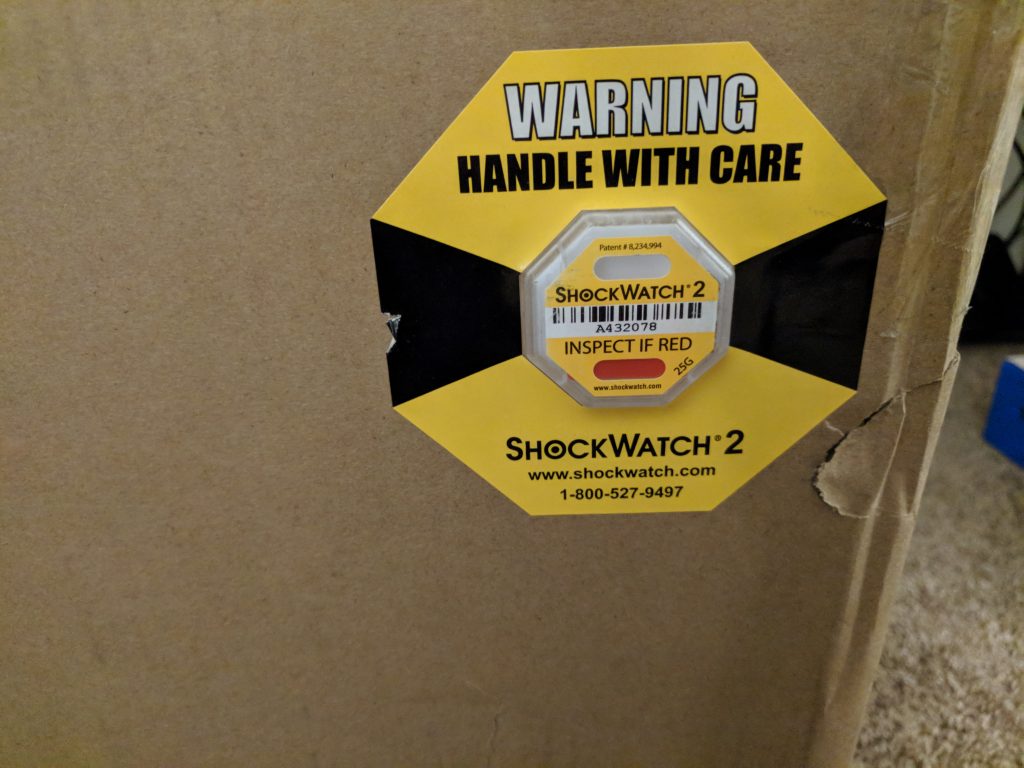

After finally seeing that other Kickstarter backers were beginning to receive their SLASH 3D printers (via the Facebook SLASH Users Group), I became envious of them and reluctantly reached back out to UNIZ to see if they would still fulfill my original order (I made the decision to not rely on UNIZ for anything after this). UNIZ accepted. After the initial annoyances of waiting forever, and dealing with UNIZ’s incompetent support and sales teams, I finally received my UNIZ SLASH on January 4th, 2018. They put shock sensing stickers on the box, which were tripped.

After unpacking everything I found that none of the Kickstarter stretch goals were included (They promised an extra resin vat, an extra bottle of resin, and an extra build platform). After emailing UNIZ, they informed me that the stretch goals would be shipped later.

I did not end up using the original SLASH a whole lot before UNIZ decided to launch their second Kickstarter campaign, but I did use it enough to be pleasantly surprised that it worked for the most part. The printer’s built-in wifi capability has never worked properly, but plugging it in to a computer’s USB port seems to work fine. On a side note, I did run into one interesting issue with one of my computers and the SLASH where the SLASH would conflict with the cheap USB wifi adapter that the computer was using, and it would effectively disable the computer’s internet when connected.

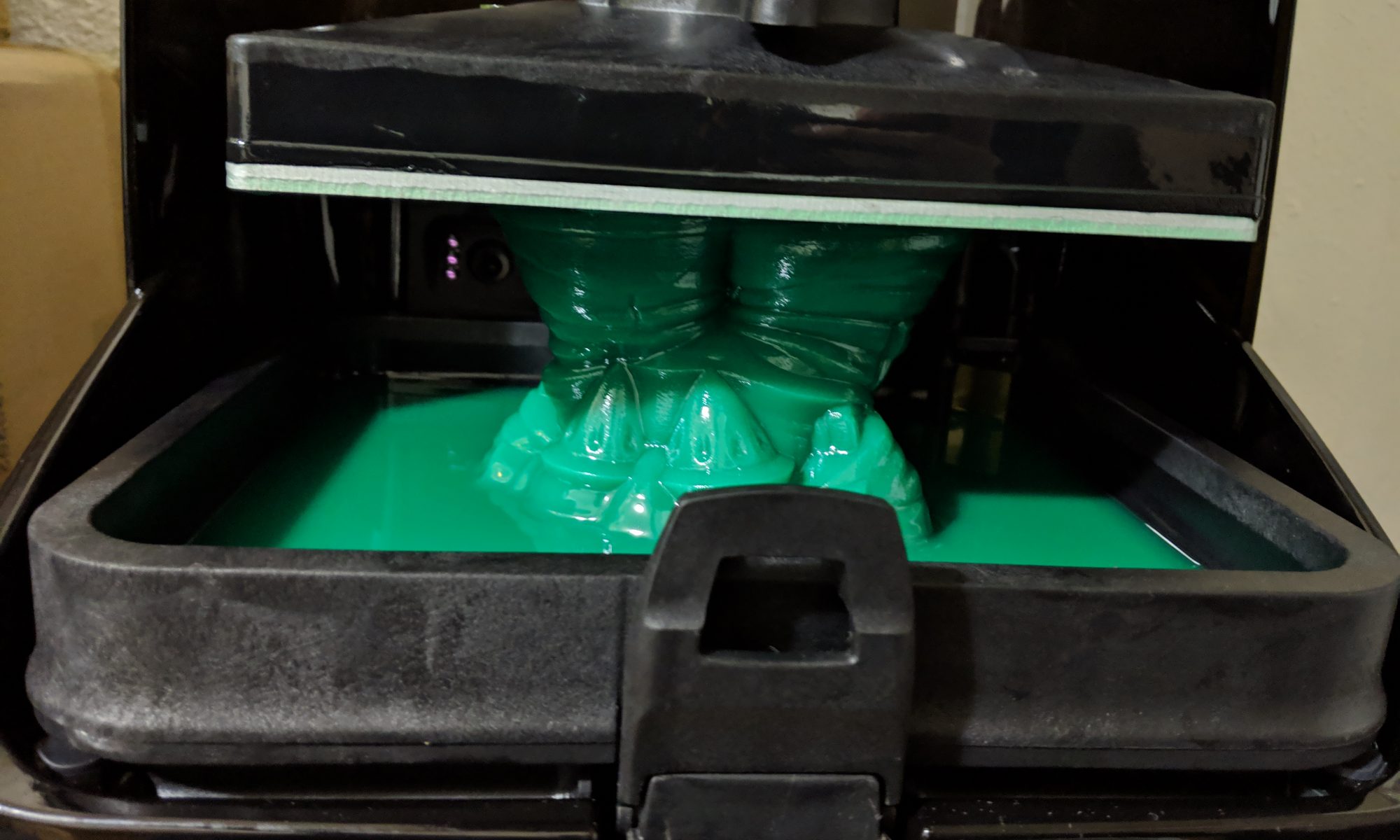

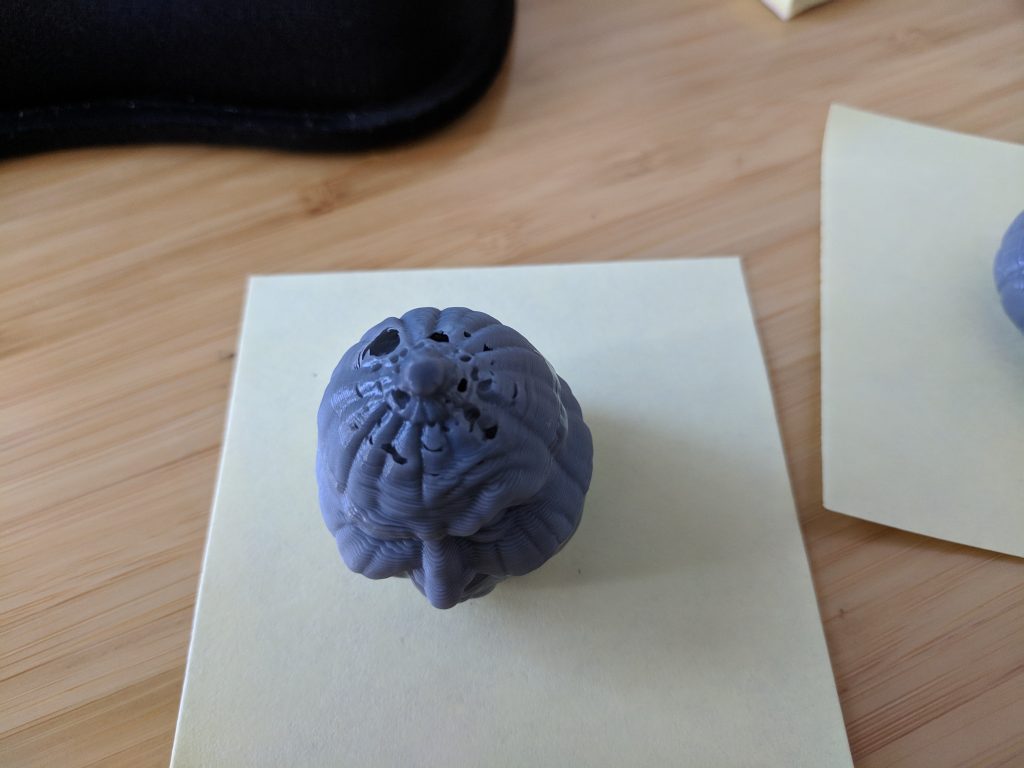

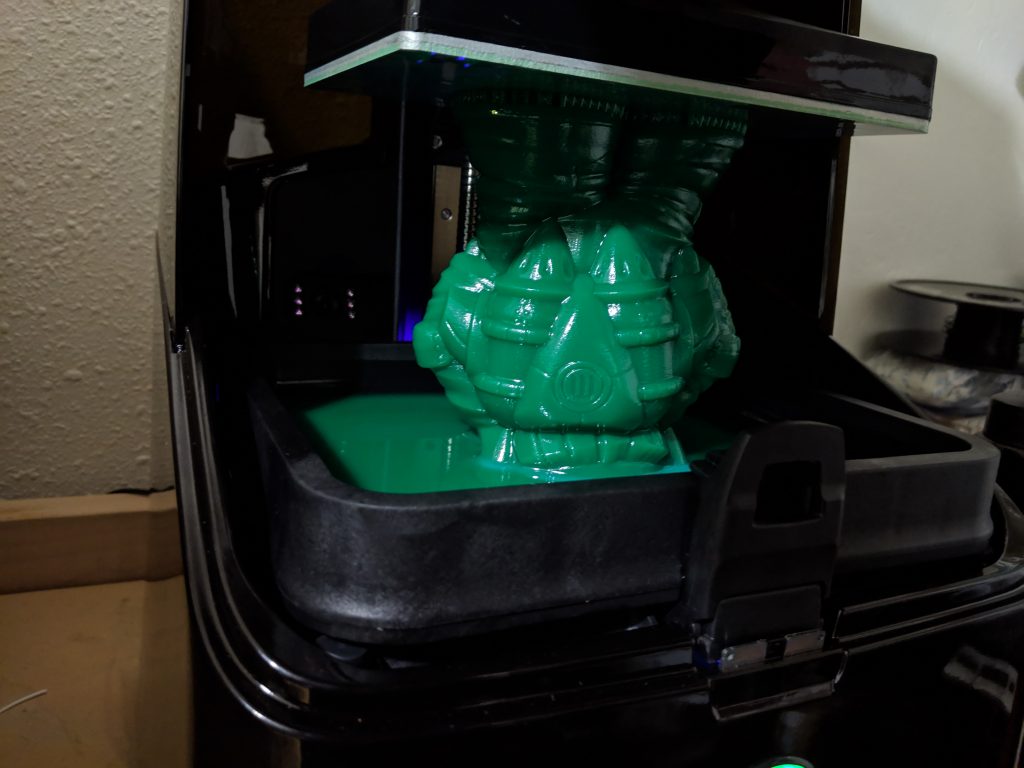

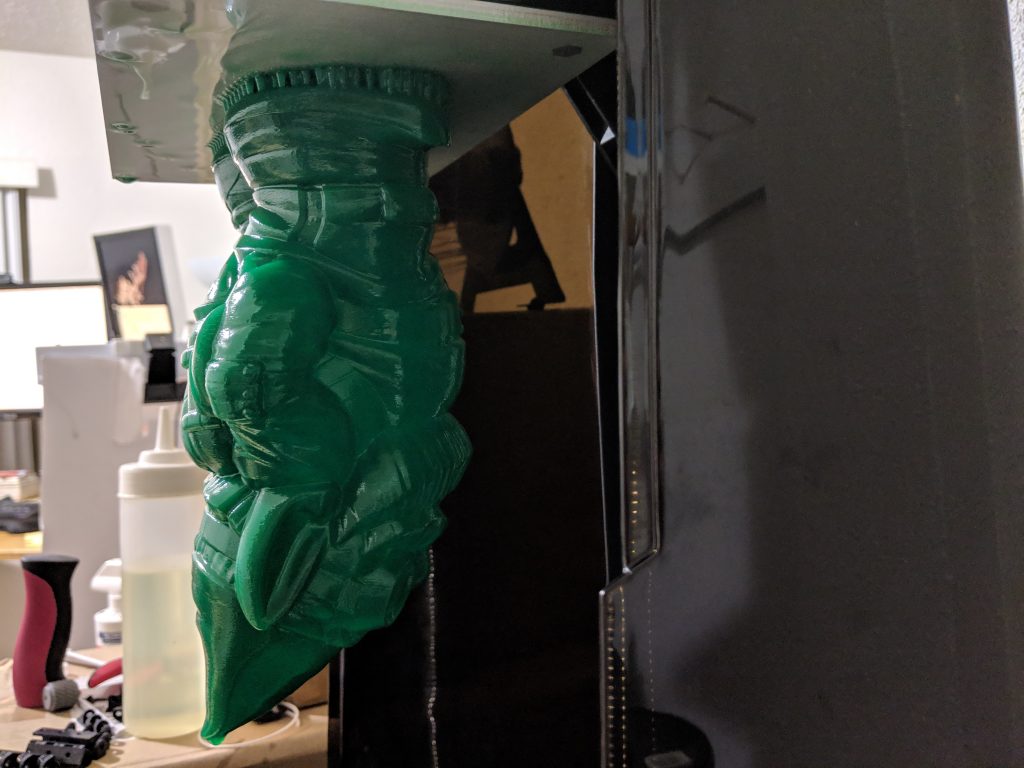

From some online discussions (especially on the Facebook Users Group) there were plenty of other issues with this machine for many people, including an issue with the liquid cooling system which caused what are being called “cooling lines.” In other words, parts would come out with visible vertical lines on them… which is pretty undesirable. Also due to the high suction forces and unfortunate plastic printer chassis, some folks have experienced twisting. Even one of my brand new, unopened resin bottles, leaked. Again however, I have not used the original SLASH that extensively… I only have a few small test prints, and a couple contract prints that went through it. I wanted to see how the details might come out when printing something very small, and aside from a failed support or two, the tiny Incredible Hulk in the images below came out quite nicely (printed at 10 micron layer height using UNIZ zABS Green).

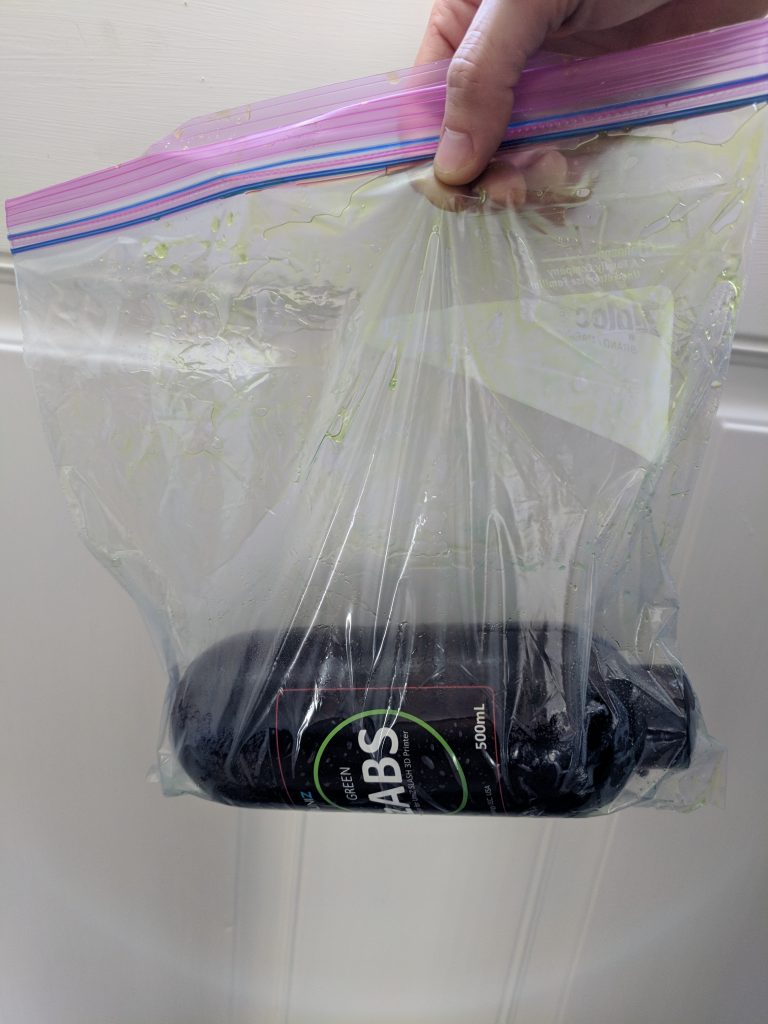

After waiting a couple months, I reached back out to UNIZ to ask about the stretch goal rewards. They gave me some BS excuses about why the stretch goals were not sent (basically referring to their confusion when I had them refund my orders), but they did eventually send out what was promised. Unfortunately UNIZ decided to send me the old build plate design which features screws for adjusting and a large air gap that resin can easily get into, but not get out of. My SLASH came with their sealed build plate design, so this seemed odd to me… but I decided to just accept it. I also experienced a few leaky bottles of resin (due to a bad bottle design), and was eventually able to get UNIZ to replace these wasted bottles of resin with their updated bottles that do not leak as easily.

Leaky Resin Bottle

Old Build Platform Design

New Build Platform Design

The initial releases of the UNIZ software definitely seemed like it came from the same company. I found the UNIZ software to be somewhat clunky, but it got the job done. More on the software later though…

UNIZ-UDP TECHNOLOGY AND THE SLASH PRO

On January 9th 2018, UNIZ launched their second Kickstarter campaign in an effort to improve upon the first (and seemingly half-baked) SLASH printer. “UNIZ-UDP: the World’s Fastest 3D Printer Technology” Kickstarter campaign reached their $30,000 goal and was “100% funded in just one hour!” The campaign closed on February 8, 2018, and “successfully raised $257,968 with 391 backers.” I had mixed feelings about this campaign after my initial experiences with UNIZ (i.e. their previous Kickstarter campaign and poor customer support), but their UDP technology sounded too awesome to pass up on (I ended up opting to trade in my original SLASH for the SLASH Pro). UNIZ claimed that:

Uni-Directional Peeling (UDP) results from over 2 years dedicated effort of UNIZ R&D team. By reducing the up-and-down peel to one-directional peel action, UDP sets a new world record of 3D printing speed to over 700mm/hr z-axis speed, without the necessity of pure oxygen or exotic separation materials.

After having already worked with Carbon’s M1 at my day job, I was blown away at the concept of being able to have a 3D printer that is just as, if not more, powerful than a Carbon printer on my desktop for a small fraction of the cost. With this campaign, UNIZ was releasing a line of new improved SLASH printers, and planned on introducing a pricing structure which included the possibility of buying software limited machines for a lower entry cost. The software limited machines would be limited to lower resolution printing, and possibly other limitations, and could be unlocked later for an additional (and pretty steep) fee. UNIZ seems to think they are Tesla or something here, and I am definitely curious how this is panning out for them… UNIZ also made the promise to deliver these new 3D printers on time (by July 2018).

DELIVERY, UNPACKING, AND

FIRST IMPRESSIONS II

As I mention in my “SLASH Pro initial test prints” post back in November, the first SLASH Pro I received from UNIZ (on October 8, 2018) was DOA.

To nobody’s surprise, the shock sensing sticker on the shipping box was tripped once again.

Once unpacked, the printer fired up, but when testing the LCD screen, I discovered that the LCD screen was not working (no image or logo would display). Not a promising start, so as much as I did not want to deal with their support team, I reached out to UNIZ about the issue. They responded relatively promptly, and after confirming the issue, they surprised me by offering to send a full replacement printer (they didn’t even ask me to return the first one, so now I have it for parts!).

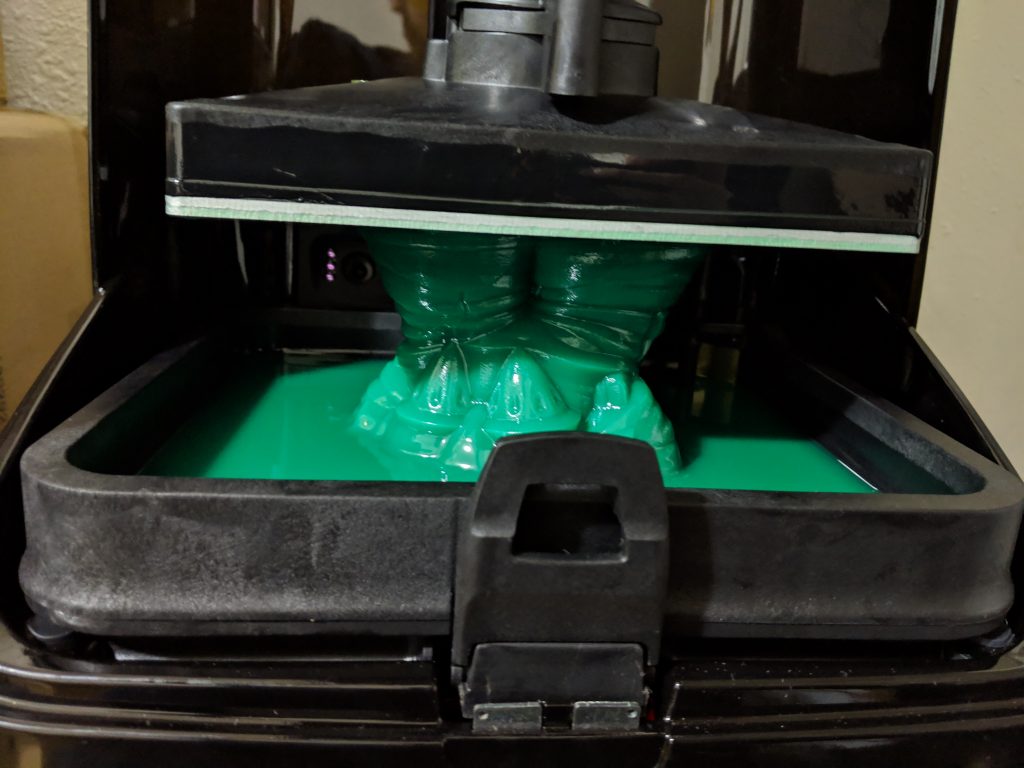

A couple weeks later I received a working SLASH Pro, and immediately jumped into action to test UDP. Unfortunately I soon found out that the UDP technology is an overall dud that was used as a gimmick to sell UNIZ’s new 3D printers. The technology has been severely underdeveloped, and is not really of any use for most use cases. I did manage to get one or two small and mostly successful UDP test prints to complete, but I also managed to waste almost two entire bottles of UDP resin just trying to make it work with slightly more challenging geometries. Since going through 3 out of the 4 bottles of UDP resin that came with the printers I received, and only getting very few acceptable results, I have stopped trying to use UDP altogether. I believe UNIZ needs to invest more in further development in the UDP resins, and especially in the hardware requirements necessary for making it a more usable technology. I really believe that one of the main things holding back the UDP technology is their low strength vat design, which uses a thin FEP (or similar) film as the interface between the resin and the light source. They need to increase the strength and rigidity of this interface by using some sort of ultra strong glass or maybe Plexiglas. A full vat re-design is an absolute must.

Along with the disappointment that is UDP and among other issues I noticed, I also discovered another fairly serious flaw which was not present on the original SLASH despite the designs being almost identical. While to the untrained eye, these parts look identical to the ones in the original SLASH 3D printers, the parts which hold the resin pump tubing and resin sensor and the mounting space on the resin vat somehow changed enough to no longer work as intended. The result was such that the resin sensor/tube holder is so loose that it refuses to stay in place when mounted into the resin vat, and it could potentially pop out at any time. Worst case scenario, this piece could pop out at the beginning of a print, and cause the LCD screen to be crushed by the build plate sandwiching these parts between itself and the LCD screen (see video below). I am not sure if this flaw has been completely fixed on the printers that UNIZ is currently shipping, but (after multiple complaints from different users) they have at least acknowledged that this is an issue, and they have offered a free printable replacement resin tube/sensor holder for download that should resolve the problem (I have not tested this yet, and it is not easy to find online). Rather than continuing to use this part of the printer, I have decided to stop using the resin pump/sensor, and have just been manually adding resin to the vat as needed.

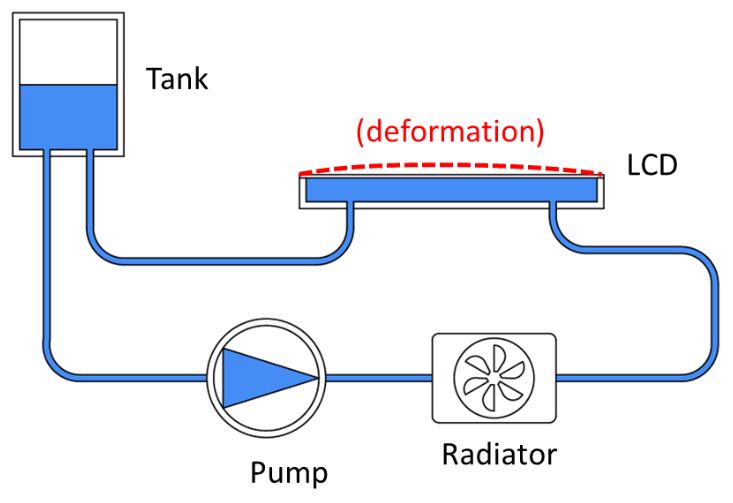

Another very annoying issue with SLASH printers is that over time, the screen cooling system will build up pressure and can cause the LCD screen to temporarily deform, which in turn can cause prints to fail. The good news is that UNIZ does have some documentation on how to release the pressure on their forum, but the process can be a bit of a headache, and appears to have been a major oversight by UNIZ’s engineers/designers (or did they leave it like this in hopes of users purchasing replacement LCD screens more often?). This now comes as a completely unexpected regular maintenance procedure that must be performed from time to time, and is an issue that no other 3D printer on the market today suffers from (as far as I know).

So aside from the various flaws and nuances I discovered with this new 3D printer, I have continued to use it every once in a while. I have not been using UDP (high speed) mode at all due to the technology’s current limitations, but the natural peel (standard speed) mode does seem to work relatively reliably.

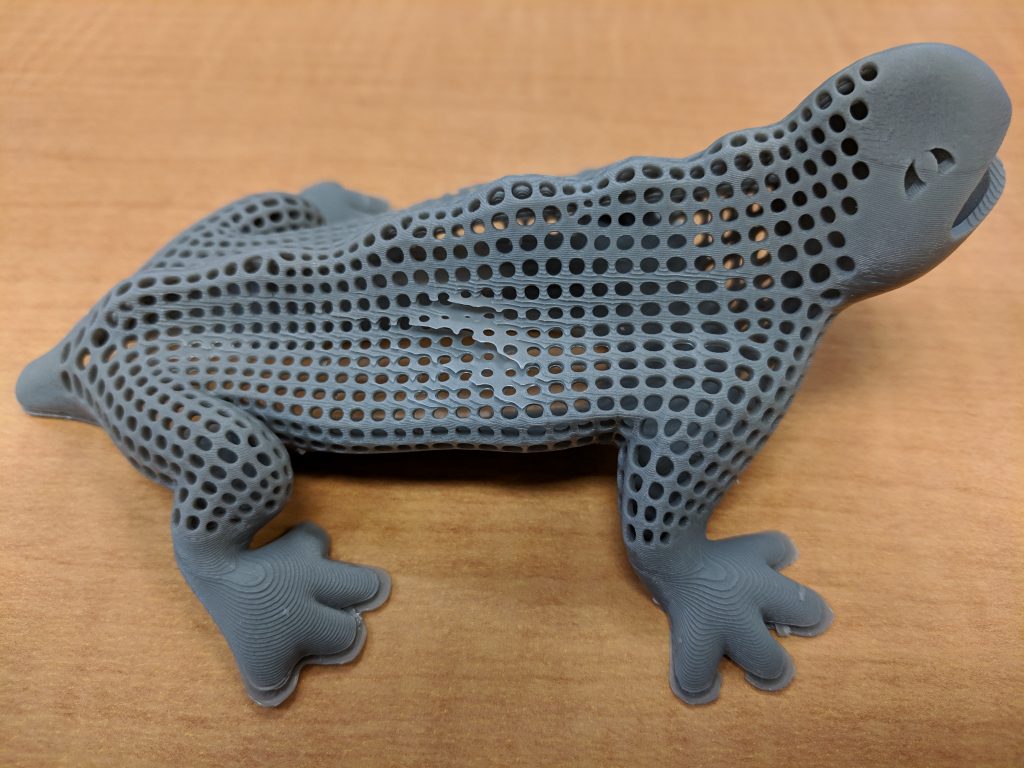

While UNIZ’s own resins do seem to work best for me so far, I have begun testing third-party resin from Monocure (their Rapid line of resins) which do seem to also work. UNIZ’s resins are a bit on the expensive side, especially when compared to third-party manufacturers such as Monocure. Some folks on the Facebook SLASH Users Group have even reported success using Monocure Rapid resins with UDP. I do not have many test prints that I can share, but below are a couple of test runs that were (mostly) successful.

4 out of 5 rooks printed, but as you can see, the one on the far left almost didn’t make it (and the others also had some slight delamination). Only the one in the middle was nearly perfect. This was likely caused by the LCD deformation issue mentioned above and/or an uneven build plate.

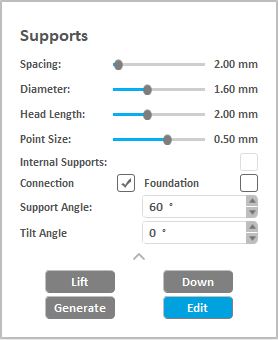

UNIZ SOFTWARE

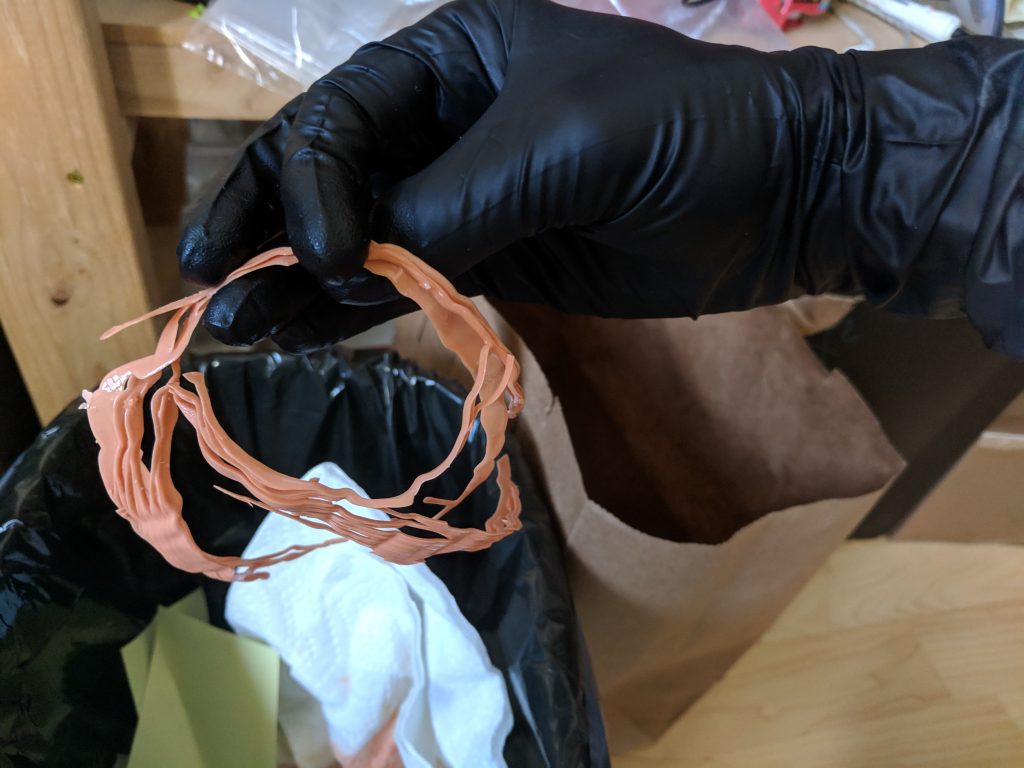

The UNIZ software works, but it definitely still has a long way to go. Today the software has certainly improved since the original SLASH, but it still seems a bit buggy and hacked together at times. While I think maybe a complete UNIZ software review can be saved for another time, I will mention a couple areas where I think the currently available software could use improvement today. The automatic support generation feature is not bad, but it is not perfect (none of the others really are either…). The user is currently stuck with the task of figuring out the best support structure settings, which can have a bit of a learning curve and require a few test prints to dial in for any given model. It would be nice if the software was able to help the user decide on some of these settings so that the print would be more likely to succeed, and so that the support material would not be too difficult to remove (especially without damaging the printed part). Until then however, it might be worth trying to add support material to your models using some other software (like Netfabb or B9’s software) first before bringing it into the UNIZ print setup software. Otherwise expect to waste a little resin as you learn how to dial in your support material settings.

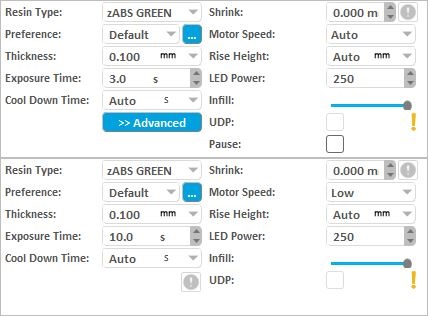

Similar to the support generation feature of the UNIZ software, the slicing settings can be a bit intimidating too. The good news is, that for the most part, I have found most of the default resin presets that I have tested to work (except for the UDP resins). However it can be a little bit of a challenge to troubleshoot issues with your slicing settings when things do not go right, and you are on your own if you plan on using any third-party resins because they are not supported by UNIZ.

SUMMARY

So, should you buy a SLASH 3D printer?

It depends…

…UNIZ SLASH has plenty of potential, and UNIZ is continuing to develop new printers and software today. If you know what to expect, and understand the risks, then I might recommend picking one of these 3D printers up. But if you are on the fence trying to decide between a SLASH or a Form 3 (or even a Form 2) and you are looking for something that is relatively easy to use, has good customer support, and is ultra-reliable, then I might suggest you go with a Form Labs product.

The SLASH is a great printer for those that are highly experienced in 3D printing or for those who enjoy tinkering and experimentation. However, in my opinion, SLASH is still very much a work in progress, and UNIZ has just been using Kickstarter as it’s initial platform to get their technology development off the ground. Now that they have run two successful Kickstarter campaigns for essentially the same products and technology, I really hope to see them start taking things more seriously as competition continues to grow. SLASH printers work, but they are not super easy to learn, especially if this will be your first printer that uses photopolymer resin.

SLASH may not be the right printer for you if you are looking for something that works well, is easy to use, and is made by a company that truly stands behind their products. UNIZ leaves a lot to be desired in the customer support department, while other 3D printer companies are absolutely nailing it. As with just about anything else, before you buy, just be sure to do your research in order to make the most educated purchase you possibly can. Otherwise, set your expectations low, or else you might get burned!

SOURCES:

https://www.kickstarter.com/projects/644653534/slash-the-next-level-of-affordable-professional-3dhttps://www.kickstarter.com/projects/644653534/uniz-udp-the-worlds-fastest-3d-printing-technology

https://www.facebook.com/groups/1386073364770734/

https://www.uniz.com

https://www.thingiverse.com/thing:993933

https://www.thingiverse.com/thing:948565

https://www.thingiverse.com/thing:138642

https://www.thingiverse.com/thing:99028

….hmmm. Though, they released a video where the “pulling” was continuous a.k.a. UDP printing. So, they did master it, but only for certain shapes, right?

In comparison to your Form 1 how does Slash perform? Ok, Formlabs printers could never come even close to the speed of a masking-LCD printers, but everything else is up to your expectation? …slicer, maintenance, build quality, liquid-cooling, resin filling, all this every day task.

Thanks,

D.

Due to the limited development of UNIZ’s UDP technology, I wouldn’t go quite as far as to say that UNIZ has completely mastered UDP just yet. As I mentioned in my review, I do not believe that UDP is a complete feature. UDP would only be more usable with further R&D (especially with a more durable resin vat). I have not tested vat durability myself, but UNIZ does advise that the current resin vats will only last about 3 print jobs when using UDP… fixing this will help vats last longer, and likely help allow for more solid models to be printed in UDP mode without issues.

I have a hard time comparing SLASH to Formlabs printers. They are very different. Formlabs is a much more experienced American company with a pretty good focus on quality and usability. UNIZ is a very new Chinese company that seems to still be figuring everything out. In my opinion, both company’s machines reflect my descriptions of the company.

Please read through my review again though… I think I go over a lot of what you are asking about in the review above.

Hi Ryan

Nicely put together. I’m wondering… so, what is the highest speed at which the SLASH printers actually run (mm/h)? Do they ever achieve advertised 120mm/h in standard “peeling” mode?

And the BIG MYSTERY QUESTION… How the hack this UDP works????? I don’t grasp the uni-directional part…

Thanks Dorjano,

Unfortunately I have not done any real speed tests, but I will say that the SLASH does live up to my expectations in terms of print speed. It is definitely faster than the Form 2 (I have not tried the 3 yet). That said, I cannot say for sure if 120mm/h is actually achieved. This can also really depend on your resin and print settings, so I’m sure using UNIZ’s proprietary resins at lower layer height/resolutions would produce a pretty speedy print.

In terms of UDP, I honestly think that UDP is nothing more than a made up name for something that UNIZ wants their printers to do, but they themselves do not really fully understand yet either (okay, perhaps it is a marketing ploy as well). The acronym, “UDP” meaning “Uni-Directional Peel,” sounds great, but UNIZ has a long way to go before they master UDP and it becomes usable for their customers.